MARINE

SERVICES

WE AIM TO PROTECT

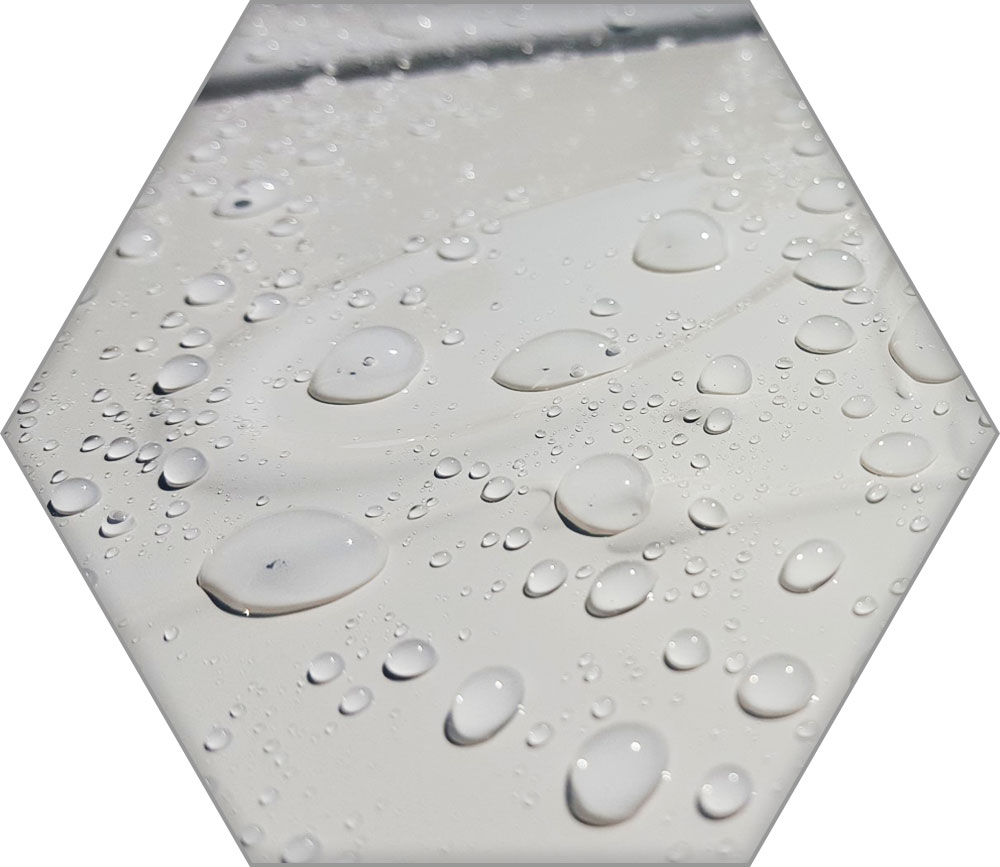

Ceramic Nano-Coatings of today will function on your fishing rig as a battle shield protecting against all attacks from the elements. Reduce frustrations and streamline your wash-downs. Save yourself $$$. Even the best equipment will oxidize under the scorch of the sun and salt air. This is the only approach if CONTROL is what you want. Find out more below.

About treatment of new boats and new surfaces – REACTIVE APPROACH

One of the most common issues we see is pre-mature surface degradation, scratches

The systems used by our team and professionals around the world are going to set your yacht finish to have a chance at fighting mother-nature. The products are smarter and work harder for the dollars spent. Keep in mind many companies will never look past the shelves of the local boat supply store for products. Distributors are found to be similar, pumping out the same old compound/restorers and wax products because the margins are good. We refuse to sacrifice quality and stay stationary with our methods. We are dynamic as a company and as individuals. We are pioneering a revolution, literally, and we want to bring all of you the best available. It’s in our DNA.

Finish polishing followed by a quality protectant is key from the start if you want a successfully shiny yacht for many years to come. We accomplish this on nano-scale tolerances which are unsurpassable by 97% of the abrasive technology on the shelf. Manufacturers, Dealerships and detail companies not having the latest in surface care products is common place. Mainstream hasn’t brought enough in to market especially on the marine side. Sub-prime, out dated products yield the same old results. A few washes and there are the swirls, then in 4-6 weeks wax begins to degrade and the best may last 8-12 weeks. This all starts right from the beginning. Risk to reward in this case is sub-par.

INFORMATION

![]()

1980 Avenue L • Riviera Beach, FL 33404 • (561) 328-7302 • info@dnasurfaceconcepts.com